View your entire die casting operation remotely.

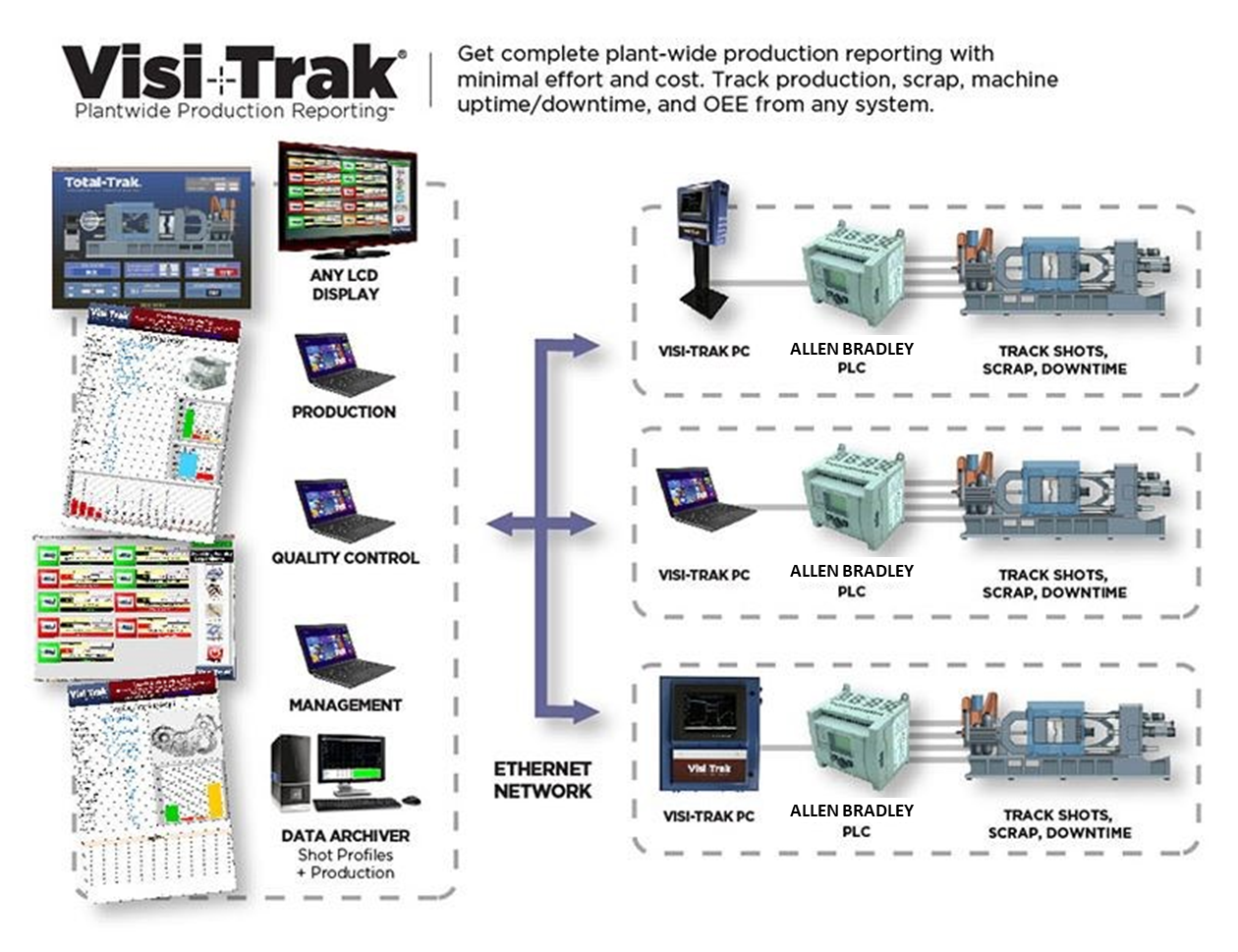

A simple software upgrade for any True-Trak 20/20 or Sure-Trak2 system. Upgrade any Die Casting Machine by connecting a few digital outputs to our low cost, preprogrammed MicroLogixPLC. Track production, scrap, machine uptime/downtime, and OEE from any system.

Availability

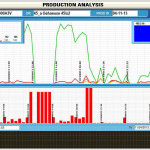

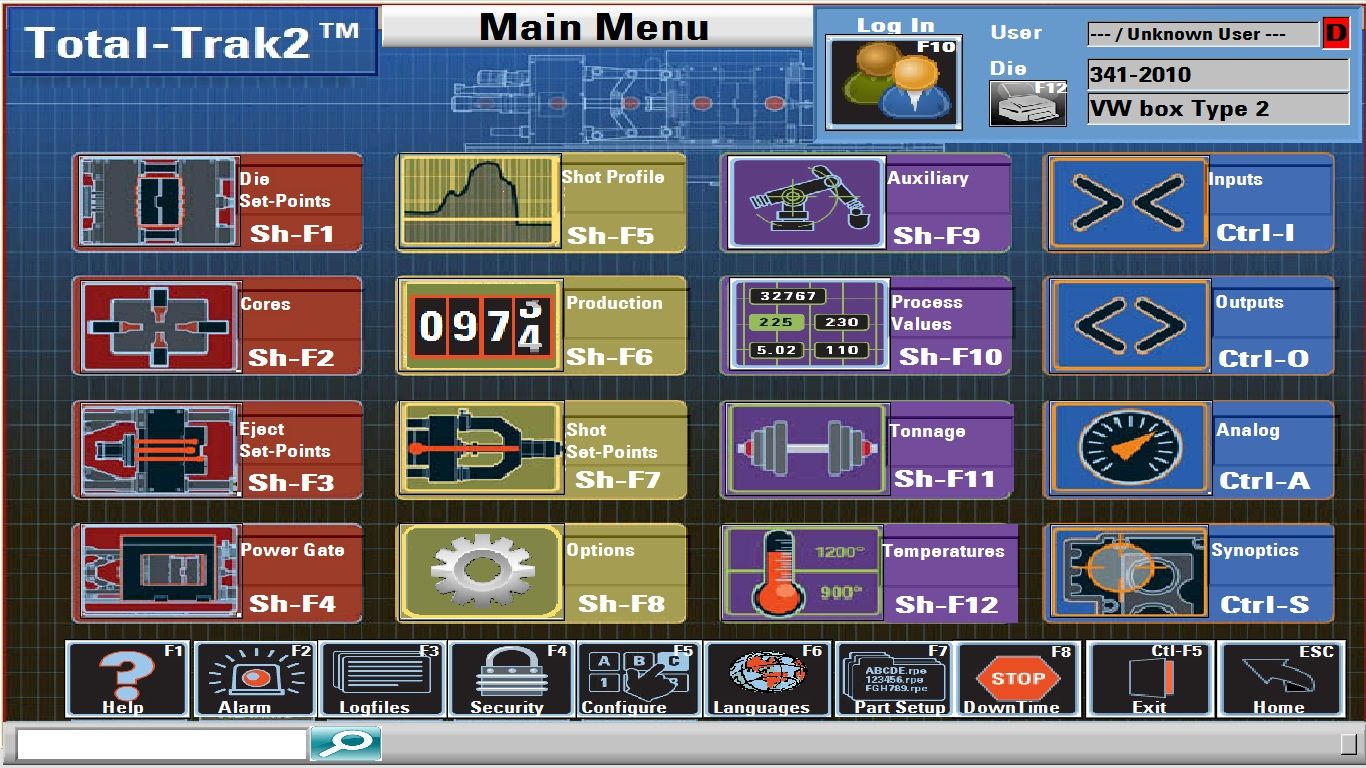

Track Downtime and Scrap Reports: with Pareto analysis of causes. Foundry View of all your machines on a single screen.

Performance

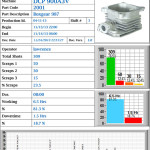

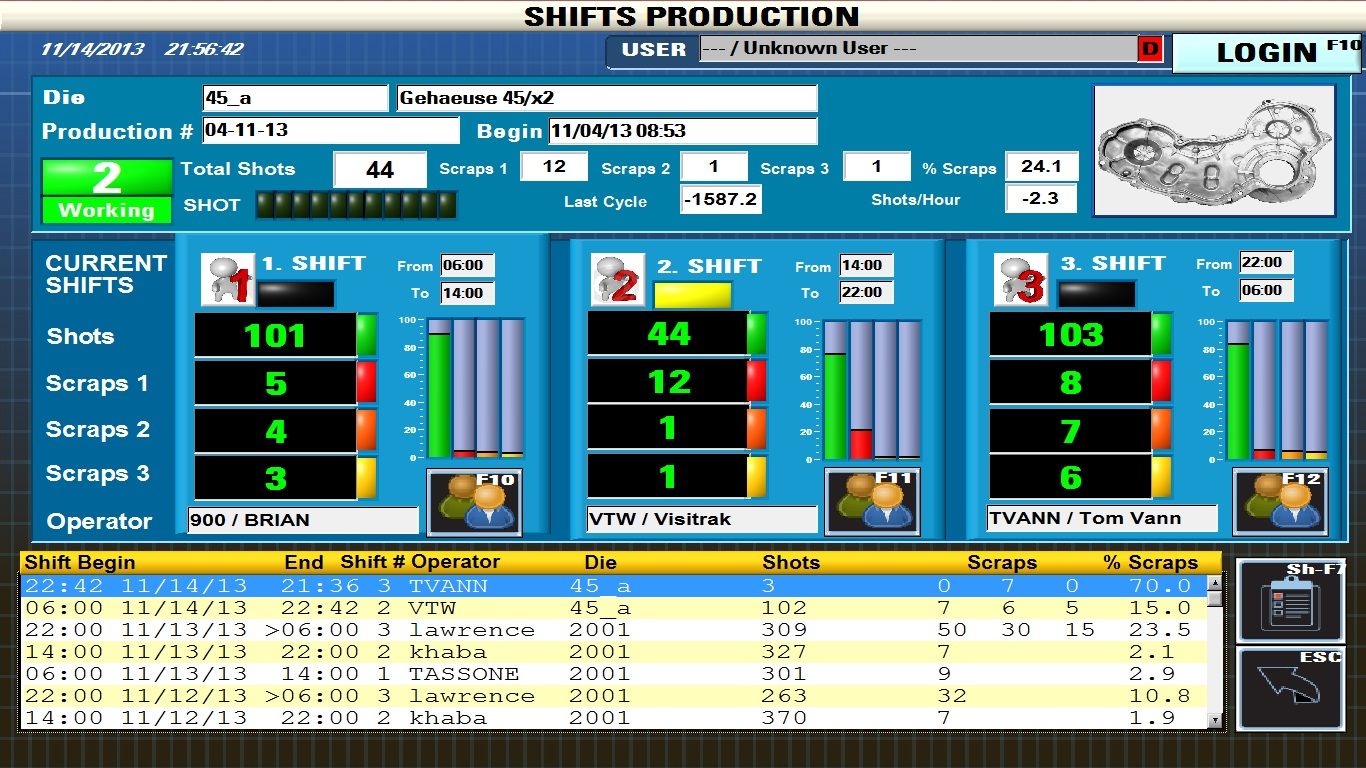

Production view by part, die, operator, shift, date, period, and machine. Reports for: castings scheduled, produced, remaining on order, and estimated time to complete.

Quality

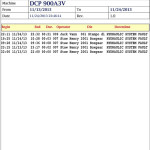

Parameter Trends, Cp/CpK, X-R Charts, Correlation with with real-time data for part, cycle time, runtime/downtime, scrap rate, and fault codes.

Predictive Maintenance Tools

Live production reporting of all your machines in a single glance.

World Class OEE with Better Data

OEE = Availability x Performance x Quality. Reduce labor by eliminating manual data entry. Make better decisions with accurate and timely data.

Increase Your Margins

All the production reports in a single format. Reduce scrap and downtime – identify machines with the highest scrap rates and most downtime.

- Production Analysis Report

- Foundry View 2

- Foundry View

- Shift Report Alternate

- Shift Report

- Downtime Reporting

- Production Analysis Report

Key Benefits for Production

Real time view of production information including Scrap, Downtime, Number of castings, OEE, etc. Integration to existing Visi-Trak hardware, tied directly into machine signals in the casting cell.

aUTOMATED TRACKING

Automatic counts for production, scrap, and downtime which should dramatically reduce your manual data entry work.

networked foundry view

Instant, accurate view of (# good parts, scrap parts, % scrap, cycle time, DCM, OEE status of entire production floor on LCD display.

CUSTOM REPORTING AND EXPORT

Automatically export production data to Odyssey and other ERP systems. Track production and scrap for multi cavity & family dies.

trigger status lights

Green, red and blue lights for uptime, downtime, and planned downtime. Quickly see machine status on the plant floor.