The Good Shots Count. The Bad Shots Cost.

Often the most significant factor impacting OEE in the die cast industry is quality. A bad shot can lead to QA headaches, re-melt costs, and die wear. In the most extreme cases, a bad shot can lead to loss of clients. Lost clients = lost profits.

So the goal is to create as many good shots as possible, leading to as many good parts as possible. Sounds simple enough, right? Only if you are using process automation. Implementing process automation in the die casting process is the key to producing good shots repeatedly and consistently.

Almost every aspect of process automation can impact overall part quality. Shot Monitoring can alert you to potential issues and Shot Control can help you avoid them altogether. As a result, both processes make sure you are adhering to established shot profiles.

Through Part Traceability and part marking, you can track every part you create from shot-to-ship and beyond. This enables you to trace parts that fail QA back to the specific shot parameters that caused the failure. Thus, future bad shots can be avoided. Your customer can then be confident that every part you produce will meet their needs. The Visi-Trak Part Traceability System completely automates the process of collecting QC shot data and adding unique part ID scripting. You can also add secondary machining data entry to capture a complete QC picture for you and your customers.

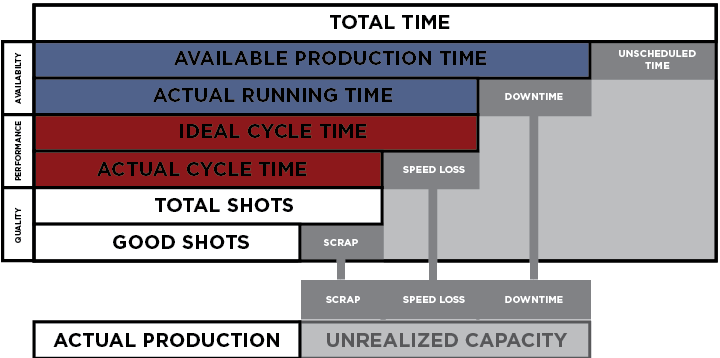

Monitor the individual components that makeup cycle time and get a real-time picture of the inputs and outputs of your entire machine cell. Discover the hidden cause of performance, quality, and availability losses.

Don’t put your business and customers at risk by wasting time, resources, and money. Start making every shot a good shot today.

Comments are closed