Foundry 4.0 and Visi-Trak

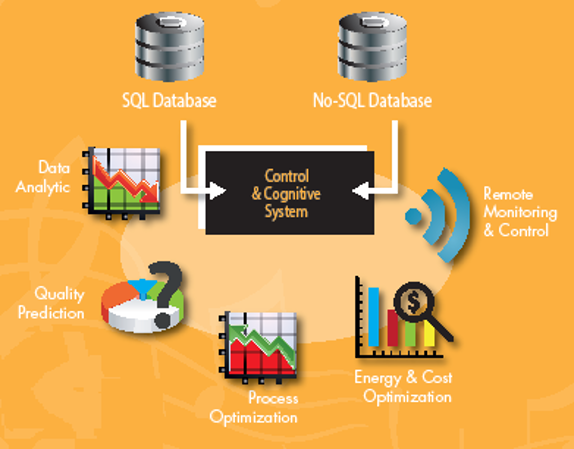

By connecting machines, work pieces and systems, businesses are creating intelligent networks along the entire value chain that can control each other autonomously.

PLC Interface

Our PLC interface via Ethernet easily communicates with many industrial communication protocols including OPC DA, OPC UA, Profinet, EtherNet/IP, etc.

predictive Maintenance

This platform gives die casters the ability to implement Foundry 4.0 while providing them with real-time, actionable data so they can take countermeasures to maximize OEE.

Automation

Automation is improved by the introduction of self-optimization, self-configuration, self-diagnosis, cognition and intelligent support of workers in their increasingly complex work.

Smart Die Casting

The Visi-Trak HMI Product Platform of products along with our Plantwide Process Monitoring System gives die casters a competitive edge with easy-to-use tools that empower you to make data-driven decisions that optimize your die casting process.

single networked view OF PRODUCTION

Optimize every shot to reduce part variability and link the entire machine cell via PLC control. Remote access, view, and control of critical parameters. Predict and avoid failures and trigger maintenance for unexpected changes. Data from post-processes in one record for perfect traceability and quick access.

HMI Platform of Products

Total-Trak2™ HMI: Full machine cell monitoring & control with EtherNet PLC interface.

PRODUCTION REPORTING

Production Reporting System: Monitor & reporting scrap, downtime, number of castings produced, OEE.

HMI Data Transfer Program

Import PLC/machine parameters from PLC to True-Trak 20/20™ software for archiving and shot parameter data.

traceability

HMI Traceability program: Interface to a marking system via a PLC.

sql exporter

SQL Exporter program: Automatically export shot parameter data directly into relational database tables.

Get a Demo

Digitalizing & Analyzing Process Control Parameters as Big Data. Data Exchange Protocols Between Different Machinery/Systems (OPC – UA). Sensorization of Die Casting Process: Die Temperatures, Vacuum Performance, Motor Pump Vibration, Consumption. Die Casting Applications and Systems related to Foundry 4.0