Consistency is the key to success in die casting because once you find your critical process, you must be able to repeat it, all day, every day. In most cases, the entire injection stroke is achieved in under 3 seconds which can create challenges with repeatability. However, which parameters are critical and why? There are several important parameters and different castings have different requirements.

Where do all these parameters and rules come from?

The die contains three primary areas where molten metal flows; the runner, the cavity, and the overflows. Die casters typically try to use the slow shot speed to get the air out of the shot sleeve and up into the die cavity ahead of the liquid metal so it can escape through the vents which are attached to the overflows. The runner system should usually be filled as fast as possible to avoid excessive heat loss in the metal. However, an incorrectly designed runner system can limit how fast the runner system can be filled. If the runner system is not designed properly, it can result in trapped air which eventually ends up in the casting. The combination of the runner design and the momentum of the metal strongly affect the cavity filling pattern. A completely different casting quality can result when using an early or a late transition point even if the die remains unchanged because the liquid metal trajectory and momentum are very different.

Some die casters with properly designed runner systems can begin accelerating the shot speed as soon as the shot sleeve is full to minimize the heat loss and maximize the possible flow length of the metal. On the other hand, if there are problems, die casters may attempt to slightly prefill the cavity and initiate the acceleration into fast shot after the runner is completely filled. This “pre-fill” can be a good strategy to minimize trapped air (especially close to the ingate), however, it will certainly limit the potential flow length of the metal. This strategy is more often found in thick walled castings (above 0.25”).

Once the cavity is full, a high static pressure (called intensification pressure) is applied to reduce the porosity (both gas and shrinkage) in the castings.

Repeatability is Key

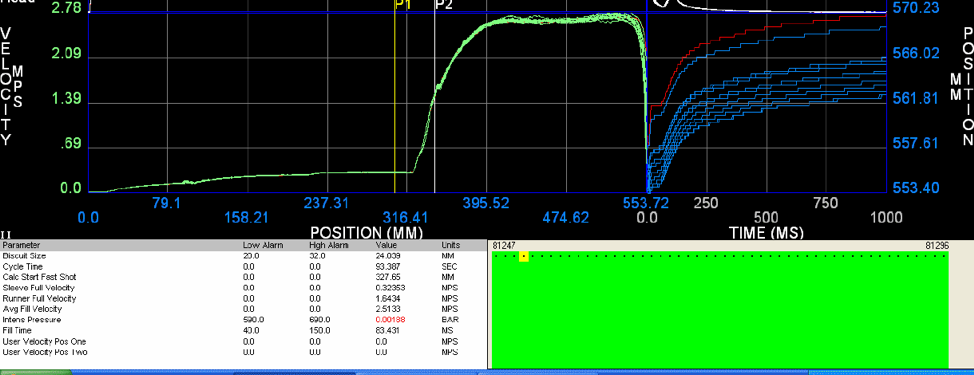

Image above displays a high degree of repeatability for the complete filling and intensification phases. All critical parameters of the shot are set with warnings and alarms. Every shot is monitored.

The most advanced way to understand process repeatability is to automatically monitor every shot with a computerized system and set limits for each of these parameters to send warnings or alarms when they fall outside of the acceptable range. For example, when castings have porosity problems if the intensification rise time exceeds 0.100 seconds, the desired time is set to 0.080 seconds, the warning is set at 0.090 seconds, and the alarm is set at 0.100 seconds. In this way, the die caster can see if the machine is getting close to having a problem or if a problem occurs, the casting is immediately set aside for closer inspection.

Visi-Trak closed-loop shot control includes:

- Visi-Trak real-time shot monitoring and control system

- Visi-Trak High Performance throttling valve

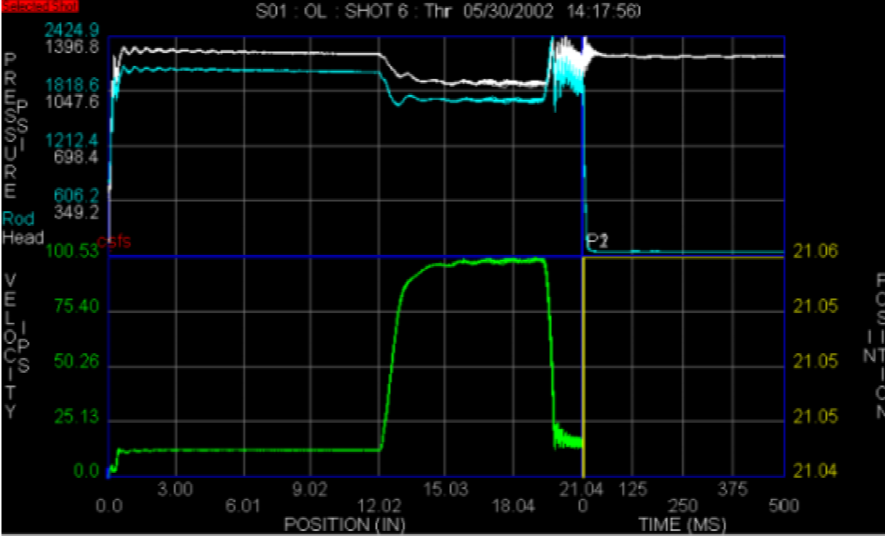

10 Shot Overlay

- Repeatable regardless of changes

- Precise and stable slow speed control

- Rapid acceleration and de-acceleration in fast shot and low impact

It can be very challenging to “find” a good die casting process. It is then even more challenging to exactly repeat the process over and over, on every casting, for the duration of the production. As the images above show, it is possible to have exceptional parameter characteristics and be able to repeat them. At Visi-Trak, we call this “Sure-Trak2 ™”.

Comments are closed